“The vast majority of Orthodontic devices we manufacture in our laboratories are related to LATE NON-NUTRITIVE SUCKING (NNS): dummy, thumb, tongue, etc. This late sucking prevents the natural placement of the tongue on the palate (low tongue) and consequently the widening of the palate, then the correct placement of adult teeth, the jaw growth, nasal breathing, sleep, etc. ”

“When our first child was born in 2015, like many parents, we asked ourselves the big question : thumb or dummy ? As we manufacture many anti-thumb devices, using the dummy was the obvious choice for us but nothing was available to stop it gently.”

— Arnaud Biezanek, inventor of Clipp

On the strength of these observations and as orthodontic professionals, we wanted first and foremost to provide our children with a dummy to MEET THEIR NEED TO SUCK and avoid the problem of thumb sucking.

Thumb sucking causes more significant deformities, weaning is more complicated and often takes longer because the thumb is 100% available 24 hours a day.

So we responded to this natural need to suck by choosing the option that we think is least harmful… and above all to AVOID THE WORST! Because this need is present from birth (it is initiated from the 9th week in utero), if there is no solution, the child will make do with whatever is available… and they are likely to find their thumb, tongue, lips, a cloth or a cuddly toy!

The Clipp kit

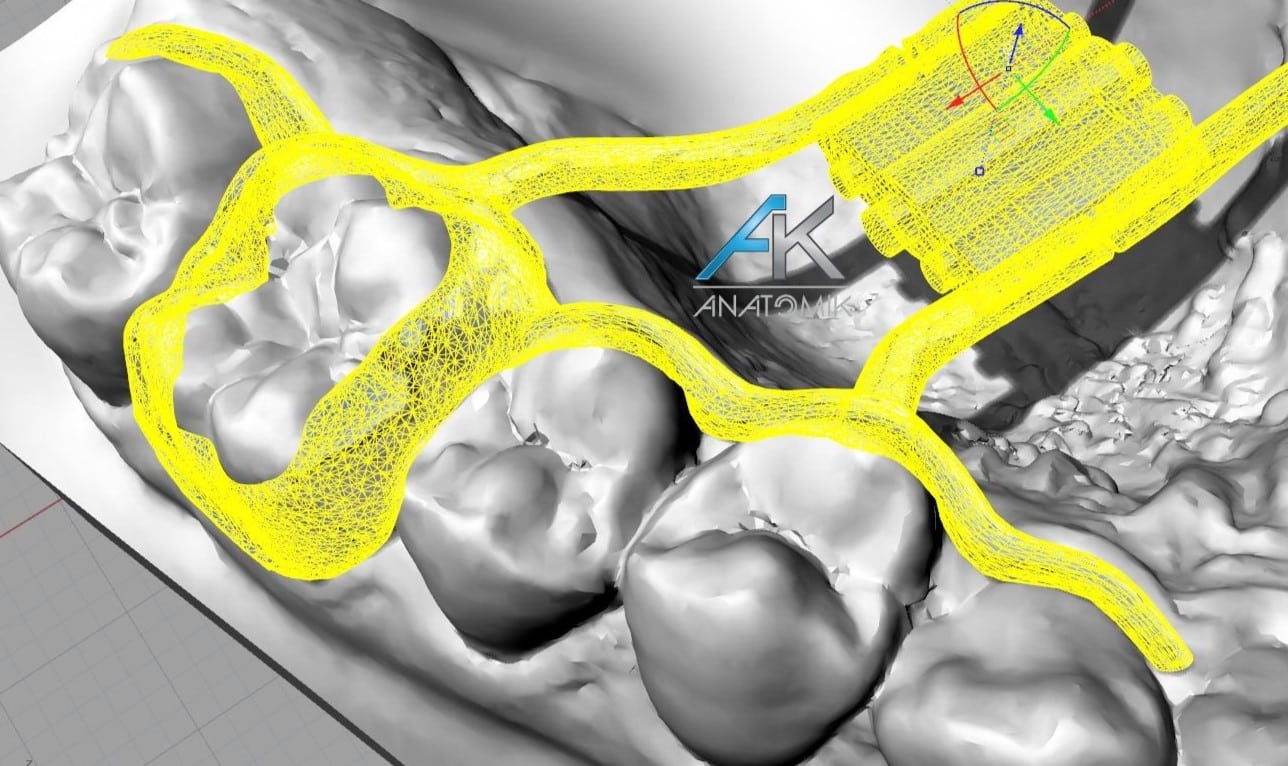

With a great team of 20 people, we now produce more than 20,000 custom-made medical devices every year for patients from the age of 3 up to adulthood. These devices range from simple dental alignment devices to pre-surgical and cleft lip and palate solutions, as well as lingual re-education and anti-thumb systems.

These made-to-measure medical devices use cutting-edge technologies such as CAD (computer-aided design), 3D printing and laser sintering. Finished devices are then sent to numerous orthodontists and hospitals in France and neighbouring countries.